Accurate screw positioning and detection with the SensoPart Hole-in-One software update

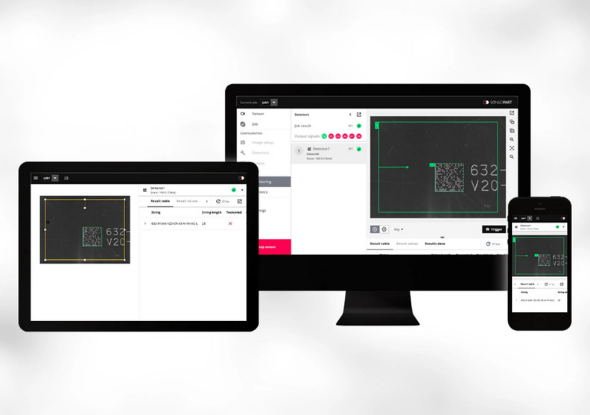

In automated production processes, it is crucial that components are assembled quickly, accurately, and reliably. The VISOR® Robotic sensor from SensoPart plays an important role in this. These cameras from SensoPart feature built-in software, eliminating the need for a separate application.

New SensoPart update for easier and smarter screw hole detection.

SensoPart continuously improves its cameras and software. Recently, SensoPart released a new software update that makes screw hole detection even easier! The latest update introduces new functions and enhancements, such as detecting screw holes and communicating this information directly to robotic systems.

Automatic screw hole detection

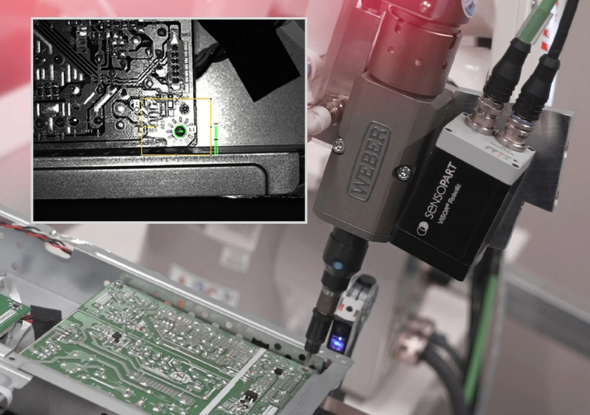

A robot must know exactly where each screw hole is located in order to assemble correctly. The VISOR® sensor first verifies whether the component is correctly positioned, then determines the exact coordinates of the screw holes and sends them directly to the robot.

Hole detection in milliseconds, insensitive to reflections.

Hole detection is performed within milliseconds, can be applied to different product variants, and remains reliable even on reflective or shiny surfaces.

Contour detector – Shape-based recognition

The Contour Check function is ideal for reliably detecting objects based on their contour, even if the object is rotated or changes in size.

Advantages of the contour detector:

- The desired contours are programmed and stored in the sensor.

- During production, the sensor compares the current image with the stored contours.

- Detection works regardless of rotation and remains reliable in any orientation.

Shape detector – Detection of geometric shapes

With the Shape Find function, geometric shapes such as circles, squares, and rectangles are detected quickly and reliably.

Advantages of the shape detector:

- Works without a reference image; results are displayed directly in millimetres.

- Shapes are automatically detected in just a few steps.

- Suitable for applications such as automated assembly or recognition of specific shapes.

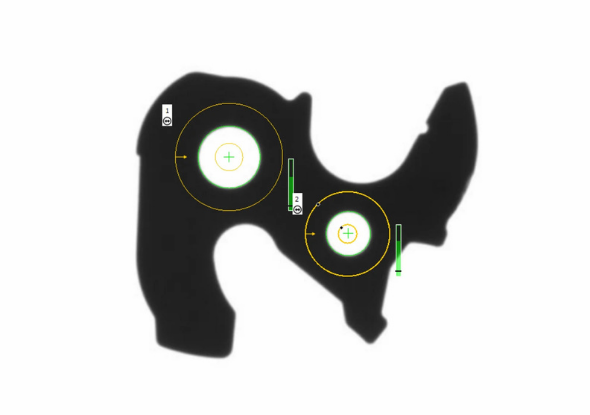

Accurate detection of round shapes for optimal process quality.

The Circle Detector (also known as Caliper or Circle) precisely measures round shapes such as holes and rings. It reliably determines the diameter and centre of complete or partial circles. Detection is fast and accurate, helping to prevent process errors and ensure consistent quality.

Spot on – Robots effortlessly recognise the correct shape with VISOR®

Automatic screw fastening

After detecting the correct positioning, the sensor immediately provides the precise location of the screw hole.

This makes it possible to:

- Quickly switch between product variants with predefined tasks.

- Detect multiple screw holes simultaneously.

- Maintain reliability at high speed, even on reflective surfaces.

Automatic calibration and seamless robot integration with VISOR®.

Thanks to built-in hand-eye coordination, the VISOR® sensor works seamlessly with various commonly used robots. Calibration takes place automatically, and position data is validated and transmitted in a standardised format.

All advantages at a glance

- Fast and user-friendly configuration of screw detection with Shape Find and Auto Find.

- Simultaneous detection of multiple screw positions.

- Direct data transfer to the robot system.

- High processing speed for fast and precise assembly.

- Fully automatic hand-eye calibration, without manual conversions.

- Compact, high-quality VISOR® hardware, easy to install.