Gain insight into your electrical installations

Society is electrifying at a rapid pace. In this way, we aim to move away from fossil fuels and achieve climate targets. Applause all around, but there is also a downside to the story. Because in a world of decentralized energy generation, renewable energy sources, batteries, etc., how can the quality and reliability of electricity be guaranteed?

A question not only grid operators must consider, but also production managers. By safeguarding the power supply and its quality, production continuity remains ensured. How can this be achieved? By measuring and monitoring. A field in which the products of Janitza, distributed by fortop, truly excel.

Text Valérie Couplez | Image fortop

Shortages and problems with power quality

Electrical installations are being subjected to increasing loads, both at home and at work. Whether investing in an electric vehicle or switching steam production to electrical energy, more electrical power is required. Electrical power that is also increasingly flowing in two directions and, due to the growing use of electronics, is becoming more polluted, a phenomenon referred to as 'grid pollution'.

“Shortages in grid capacity or problems with power quality can, in the worst case, lead to a complete outage, but in any case result in unnecessary energy losses and maintenance costs,” warns fortop director Harmen Sikkema. “Complexity is increasing. There is more and more regulation, greater pressure to save energy, and higher demands are being placed on uptime.

Expert knowledge is therefore crucial, yet increasingly difficult to find, leaving many industrial companies ‘blind’ to what is happening within their electrical installation.”

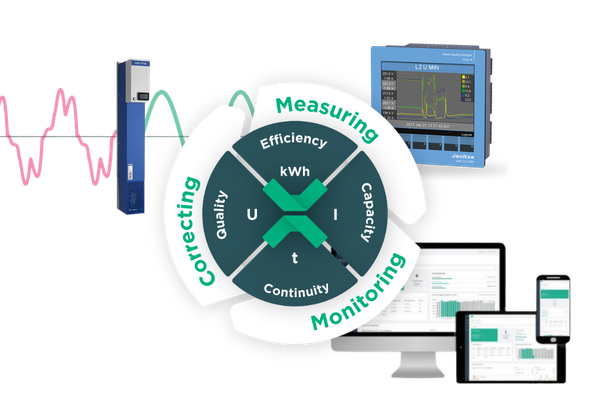

Measuring, monitoring, and improving four management aspects

fortop therefore collaborates with a university of applied sciences in the Netherlands to write a whitepaper on this issue and help better safeguard the knowledge. The starting point is the four management aspects of electricity. Sikkema: “By this we mean capacity, quality, energy efficiency, and uptime. Based on these, it can be determined exactly what an installation needs.

Measuring is knowing

Measuring is knowing and forms the foundation. With power analysers, all parameters affecting these four aspects can be mapped out. By monitoring, insight is gained into what is being measured. The collected data is then converted into actionable insights through analysis tools, notifications, and reports. This leads to improvements, for example by adapting or expanding the installation, but also through the application of UPS systems, voltage regulation and stabilization systems, or active harmonic filtering systems.”

Smarter grids, what about your machines?

A continuous process, therefore, that will only grow in importance. “The grids are becoming smarter, but industry must also know what is happening within its own factory walls. The closer installations operate to their maximum load, the more problems will arise. Compare it to a car constantly driving at 200 kilometers per hour. That takes its toll. Real insight is needed into machines, energy consumption, and where optimizations are possible,” says Sikkema. A process that also requires reliable equipment.

fortop therefore resolutely chooses the quality of the German market leader Janitza. “Energy measurement and monitoring is the core activity. Through this sharp focus, Janitza distinguishes itself with expertise and corresponding quality. The product range is very broad, from large to small, and from main distribution to end users.

In addition, the meters feature an integrated web interface in which an initial analysis of the data already takes place, without the need for additional software. An excellent starting point to begin the cycle of measuring, monitoring, and improving.”