How Inxpect 3D radar sets the standard

As industry continues its rapid adoption of robotised automation, ensuring operator safety while maintaining productivity has never been more critical. In this article, Carrick Hill, business development manager at fortop Automation & Energy Control, explores how the latest advancements in safety-certified 3D radar technology are setting new standards for restart prevention in line with EN ISO 10218-2:2025.

Drawing on fortop UK’s expertise in integrating cutting-edge safety solutions, Carrick discusses the challenges manufacturers face, the unique benefits of radar-based presence detection, and why fortop UK’s partnership with Inxpect positions them at the forefront of safeguarding industrial environments for the future.

The drive for smarter, safer automation across industry continues at pace, and as industrial robots and automated systems become more prevalent, ensuring operator safety without compromising productivity is paramount. At the heart of this challenge lies EN ISO 10218-2, a crucial standard in safeguarding robotic systems, and one of its key stipulations – restart prevention – has now found ideal partners in the form of fortop UK as integrators and Inxpect with its safety-certified 3D radar systems.

The requirements of EN ISO 10218-2

EN ISO 10218-2:2025 sets out the safety requirements for the integration of industrial robots and robot systems, focusing especially on minimising hazards and ensuring safe operation in collaborative and traditional robotic applications. One of its central requirements is restart prevention, ensuring that a robot or system cannot automatically restart while a human may still be present in a hazardous area.

Key requirements of EN ISO 10218-2 include:

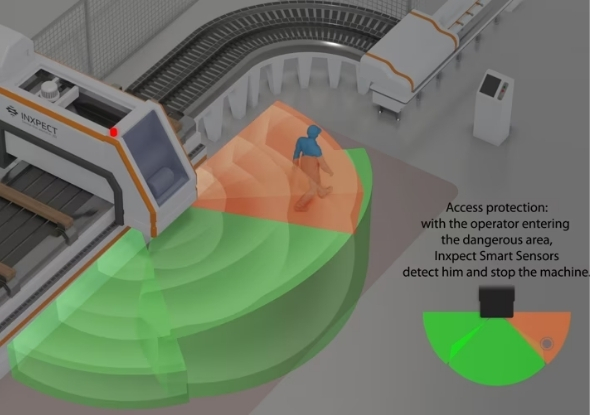

- Visibility of Safeguarded Spaces: All safeguarded areas must be visible from control stations. If this is not possible, presence sensing technology must be installed to detect human presence within the hazardous zone

- Presence Sensing: Where visibility is compromised, reliable presence detection systems (like sensors or radar) must be used to ensure no operators are present before allowing a restart

- Sequenced Reset Devices: If presence sensing is not feasible, time-limited, sequenced reset devices should be installed inside the safeguarded area. However, the final reset must always occur from outside the safeguarded area and must be inaccessible from within, ensuring that no one can inadvertently restart the system while still inside

- Emergency Stop Functions: The system must have a single emergency stop function that halts all robot motion and hazardous functions within the cell. The span of control for emergency stops must be clearly marked and remain functional even if the control station is inactive

- Risk Assessment & Hazard Reduction: Integrators like fortop UK are required to identify hazards, assess risks, and implement safeguarding measures such as physical barriers, prence sensing, and supplementary protective measures (e.g. training, signage, PPE, etc.) to adequately reduce risks

- Full-Body Access Considerations: For areas where operators can fully enter the safeguarded space, special attention must be given to prevent unexpected restarts, including the use of interlocks, time delays, and audio-visual warnings as necessary

- Documentation & Training: The standard also mandates that necessary information for design, operation, and maintenance is provided, and that personnel are adequately trained in safe procedures

Commenting for fortop UK, Carrick says: “These requirements ensure that integrators apply robust, adaptable, and proven technologies to protect operators, with a particular emphasis on preventing hazardous restarts and ensuring all safety measures are validated and maintained.”.

The benchmark for restart prevention

While traditional safety devices like fences, light curtains, and laser scanners have dominated the scene, they sometimes fall short in flexibility and environmental resilience. However, Inxpect’s radar-based safety radar equipment brings a fresh, powerful answer to this problem.

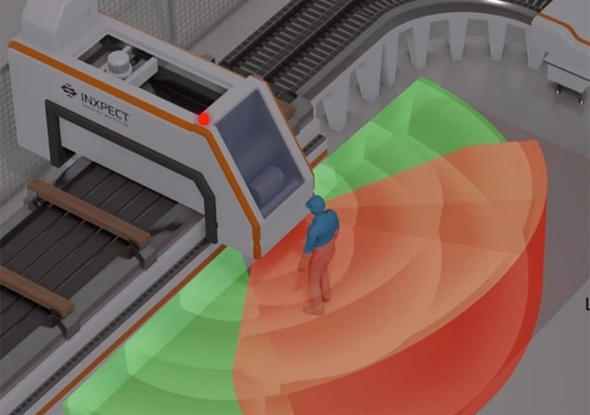

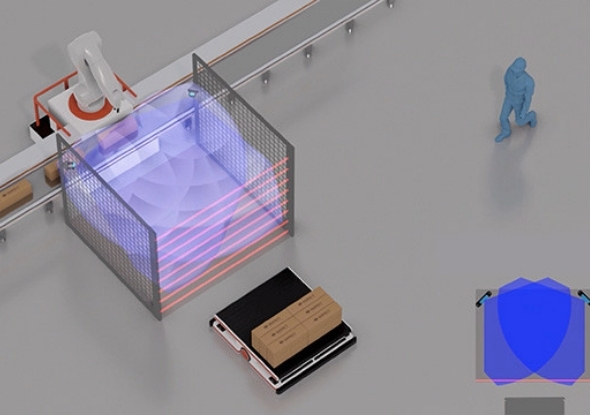

Unlike 2D systems that struggle with environmental change or partial obstruction, Inxpect’s 3D radar technology offers volumetric coverage, detecting movement throughout an entire zone, even if the operator is, for example, lying down, obscured by pallets, or moving through fog, dust, or debris.

Each radar sensor can also monitor up to four independent detection fields, with a configurable range of up to nine meters and a maximum detection speed of 4 m/s, ensuring effective protection even in fast-moving or large-area applications.

Video: Protection against access to hazardous areas

Why fortop UK is the right partner

As specialists in factory automation and machine safety, fortop UK has a long-standing reputation for delivering tailored safety solutions across multiple industries. With extensive expertise in both 2D and 3D safety system integration, including light curtains and safety-certified radar technologies, we are well placed to guide customers through the implementation of restart prevention systems that are fully aligned with EN ISO 10218-2.

From design and consultancy to after-sales support, fortop UK can support manufacturers throughout the safety lifecycle. “Working with fortop UK means gaining access to not just the technology, but the engineering insight to ensure that systems are specified, installed, and validated correctly.” says Carrick. “Our partnership with Inxpect makes us an established provider of radar-based solutions that enhance operator safety without sacrificing efficiency.”.

Traditional vs. Radar technology

| Feature | Safety Laser Scanner | Inxpect Safety Radar |

|---|---|---|

| Monitoring | 2D | 3D volumetric |

| Environmental Robustness | Low (dust/fog prone) | Immune to debris, fog, rain |

| Installation Flexibility | Moderate | Ceiling, wall or floor mount |

| Maintenance | Requires optical cleaning | No optical surface –maintenance free |

| Restart Prevention | May require add-ons for compliance | Certified (within complete safety system) for full-zone clearance |

| False Alarm Robustness | Low (motion-focused) | High (robust across all environments) |

Certified for safety, built for industry

Inxpect’s radar systems meet the requirements of SIL 2, PL d, and Category 3, meeting the highest safety requirements for industrial applications in accordance with EN ISO 13849-1 and IEC 62061 and offering certified safety functions within the complete safety system, including:

- Access detection: stopping machinery when personnel enter hazardous zones

- Restart prevention: ensuring restart only when all personnel have exited and the area is verified as safe

For end-users, these certifications translate to trust in safety systems, reduced downtime, and regulatory compliance, with technologies like those from Inxpect’s undergoing exhaustive validation by third parties to ensure they meet global safety benchmarks without compromising operational efficiency.

The flexibility of radar makes it especially suited to complex machinery and dynamic environments – including pallet wrapping stations, Autonomous Mobile Robots (AMRs), AGVs, and CNC machinery – where other systems might require frequent recalibration or cause unnecessary stoppages.

Real-world impact

A typical use case is automatic pallet wrapping machines, where restart prevention is essential but traditionally difficult to implement without overly complex safety systems. Here, Inxpect’s solution integrates seamlessly with existing fences and light curtains but offers superior human detection across the monitored area, regardless of pallet size, position, or operator behaviour.

This allows operations to avoid costly false alarms or downtime, while significantly enhancing compliance with EN ISO 10218-2. Importantly, Inxpect’s radar doesn't replace existing safety measures but adds an additional layer of smart detection.

In harsh industrial settings, like woodworking or food and beverage, this robustness is critical. Radar not only reduces the need for complex optical alignment and cleaning but also minimises false positives and improves uptime.

Conclusion

EN ISO 10218-2 does not specify a particular technology for restart prevention, instead allowing manufacturers to select the most appropriate solution for their application. However, Inxpect’s 3D radar technology has been independently certified to meet SIL 2, PL d, and Category 3 safety standards, providing reliable detection of human presence even in challenging environments.

While initial deployment may require investment and training, field data from palletising and CNC machining applications indicate a reduction in false alarms and improved uptime compared to traditional light curtains and laser scanners.

Concluding, Carrick Hill says: “As part of our mission to champion innovation and safety in industrial automation, we believe that the Inxpect 3D radar system represents a significant development in restart prevention technology. It’s time to consider moving beyond the limitations of 2D detection and adopt volumetric, intelligent 3D sensing that safeguards workers without slowing productivity.”.