10 reasons to measure permanently

1. Measurements of incidents

2. Determining space in the installation

3. Safety

4. Continuous improvement

5. Burden of proof (legal framing)

6. Preventive and performance-oriented maintenance

7. Registration of consumption

8. Recording of trends

9. Notifications and alarms

10. One-time investment

From snapshot to continuous insight

Insight into the electrical installation is a must for a company. You can achieve this by measuring temporarily or permanently. What do you choose? Is a temporary measurement a logical choice? The answer to that is no. With a temporary measurement, you only take a picture of the installation, a snapshot of a continuously moving landscape.

Production processes, weather conditions and seasons all have an influence on the power consumption and failures will occur unannounced. A permanent measurement acts as a film, capturing all necessary data for analysis and reporting.

1. Measurements of incidents

Voltage fluctuations, current spikes, and adverse effects during switching operations can result in unpredictable, operational malfunctions. Continuous monitoring enables the detection and recording of voltage dips and current spikes. Analysing this data helps differentiate whether these fluctuations originate from internal equipment or the power grid, facilitating quicker response and appropriate actions. Timely detection and reporting of such fluctuations can significantly reduce consequential costs by up to 80%.

2. Determining the space in the installation

A snapshot is not sufficient to determine the available power space on the transformer, generator or free group. In addition to a day or a week profile, the consumed power can also differ greatly over the course of a year. For example, chillers or heat pumps can exhibit peak loads in summer or winter. That is why permanent insight into data over a longer period is necessary.

3. Safety

Conducting temporary measurements poses safety hazards. Typically, these measurements are conducted on live installations, requiring highly skilled personnel equipped with safety gear, like protective screens, insulation mats, and gloves. Additionally, the work area must be cordoned off. Organising these safety measures is essential for temporary measurements.

To ensure that all this is not necessary, it is recommended to place a permanent measurement during, for example, regular maintenance work.

4. Continuous improvement

Continuous improvement plays an important role in management processes. In these cases the PDCA cycle is used (Plan Do Check Act). This is reflected in, among other things, energy management (ISO50001), optimisation of production processes, power quality management and the realisation of environmental objectives. A permanent measurement - and therefore a permanent measurement system - fits perfectly within this way of working. Periodic reports are generated automatically and are essential for the 'check' within the PDCA Cycle.

5. Burden of proof (legal framing)

Legal framing and the creation of a burden of proof is important in liability issues involving expensive machinery and equipment.

Warranties expire in case of too much harmonic pollution or too high a voltage. Hence, it's crucial to continuously monitor voltage compliance with international standards throughout the year, every day.

6. Preventive and performance-oriented maintenance

By continuously measuring the load, the power quality and unwanted neutral and earth fault currents, it is possible to intervene before a fault situation occurs and helps prevent premature failure of equipment or protections. A 'traffic light' report helps to interpret measurement data that is difficult to understand. That is why permanent measurement is a necessary tool to better plan maintenance and prevent downtime.

7. Registration of consumption

Continuous measurement is a must for measuring, registering and reporting energy consumption. In this way, the effectiveness of energy-saving measures can be proven, standby consumers can be traced and necessary reports can be drawn up. Permanent measuring and recording are necessary for every energy management system.

8. Recording trends

If you don't measure continuously, you don't see any problems coming. You are in fact blind to what is going on in the installation.

Continuous recording of data enables the identification of trends and correlations between events within the installation, external conditions, and their impact on consumption, reactive power, and power quality.

This provides a better insight into the behaviour of the installation and timely, appropriate measures can be taken. Read more about reactive power reduction in the white paper.

9. Alarms and notifications

It's desirable to receive timely alerts in case of undesired deviations in consumption, load, power quality, or voltage fluctuations, enabling intervention and potentially preventing unplanned outages. A permanent measurement makes it possible to give a timely warning via e-mail, SMS or alarm overviews.

10. One-time investment for a long-term result

The combined costs of a temporary measurement are often higher than the price of purchasing and placing a permanent measurement.

The expenses associated with a temporary measurement include the installation of a measuring case, rental fees, necessary security measures, case removal, and manual reporting, all added together.

Because it is a one-off activity, an investment in a permanent measurement yields more returns.

A permanent measurement in your installation?

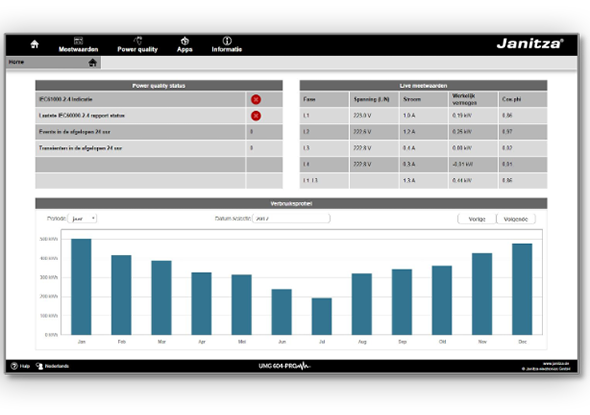

Then choose an analyser from Janitza with memory and built-in web-based visualisation. This is suitable for any common web browser for PC's and mobile devices. Software is therefore not immediately required, and you have all the benefits that permanent measuring can offer you at relatively low starting costs.

Please feel free to contact us so that we can help you choose the right energy measurement device or draw up a complete measurement plan.