Protection of robot cells with safety light curtains

Work safely and efficiently with switchgear in closed machines

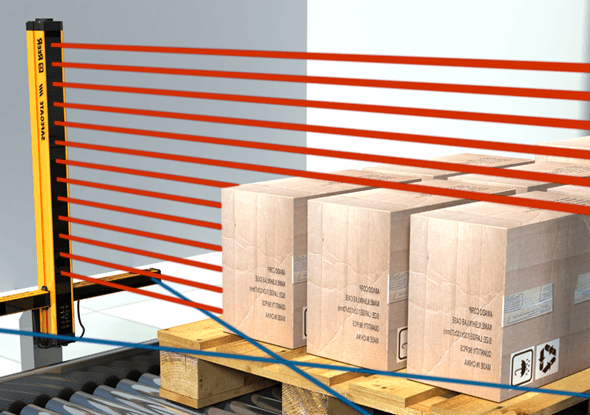

Situation sketch

In this application example, a conveyor belt transports cartons to two robot palletizing cells. The technical installation is fully protected by a gate with three entrance gates, for every robot there is an access door and there is access to the conveyor belt. The entrance doors are equipped with a safety switch and solenoid locking switch. As soon as the gateway to a robot is opened, the robot stops. When the access door to the conveyor belt is opened, the entire machine stops.

Protection with safety light curtain

The finished pallets are picked up by a forklift truck. The access gate to the finished pallets is protected and secured by a safety light curtain. The safety light curtains prevent the machine from starting from the rest position. An incoming forklift truck is detected because the light curtain is interrupted and the robot cell stops. As soon as the truck comes out of the safety zone of the safety light curtains, the safety relay switches to a safe situation.

Access security

Not only when retrieving the completed pallets do the robots switch through the detection of the light curtains, as soon as one or more rays of the light curtains are blocked, the robot in question switches off. This can also happen, for example, once an employee passes through the protected area. The manual restart button is located near the safety light curtain. The system is equipped with four emergency pushbuttons (e-stop). Read more about light curtains with muting function.

Safety components in the application example

Door switches/safety switches

In the application example, various safety components are used to protect people and machines for unsafe situations. Door switches are used for access to the robot cells. Read more about safety switches for doors, windows and valves.

Safety light curtains

The forklift truck and other objects that want to enter the unsafe zone of the machine are protected by two safety light curtains. The safety light curtains are equipped with two separate reset buttons for restart. Read more about safety light curtains.

Emergency-off buttons

As the final safety component, there are 4 emergency-off buttons in this application example. The emergency stop buttons by steute are provided as additional safety or last stop means in the technical installation. Read more about push buttons and control switches.

View all machine safety products and read more specifications

Configure your security with safety light curtains

Conventional safety components

In order to build up the safety circuit with conventional safety components, at least 6 safety modules should be used, which must be connected to perform the required functions. 2 safety relays for the light curtains, 3 relays for the slide switches and 1 relay for the emergency stop buttons.

Solution with programmable safety relay | Mosaic:

When using the programmable safety relay Mosaic from ReeR, the following 2 modules are sufficient to install the safety circuit:

The reset buttons are not included in the diagram because they are directly connected to the feedback from the OSSD safety outputs. The 4 e-stop buttons are included in the diagram as a single block.

The programmable safety relay Mosaic - Safety PLC from ReeR Safety is easy to configure using 'drag & drop software'. With this you are able to set up your own safety system that fully meets your wishes and requirements. The software provides a clear overview of the situation, making functions easy to add.

Application example: protecting robot cells with light barriers

More application examples

Read more about application examples for machine safety with safety PLCs and safety switches.

Application examples:

Stay up to date of our latest news

Analogue input module MA2/MA4 for Safety PLC Mosaic

Analogue input module for safety PLC - Safety cont...

Read more 07/01/2019Light curtains for car washes and ATEX environments

Waterproof housing EOS4 WTHF light curtains for ap...

Read more 09/10/2018Renewed main module Mosaic M1S

Renewed main module Mosaic M1S The Mosaic M1 main...

Read more 26/04/2018New 5 mm resolution for detecting small objects

New 5 mm resolution for detecting small objects -...

Read more