Power management: Essential in modern electrical installations

Technical challenges in healthcare facilities

Technical managers in hospitals and care institutions are facing increasing challenges. A wide range of energy-saving measures must be implemented, while at the same time, the growing use of electronic devices and the resulting network pollution are placing greater strain on the reliability of electrical installations.

Electricity supply in hospitals

Over the past few decades, hospitals have witnessed a significant rise in the use of electronic medical equipment. CT scanners, MRI machines, X-ray systems, dialysis machines, and surgical robots have become essential to modern healthcare. These technologies continue to evolve, enhancing productivity and reducing the average time required for patient care.

At the same time, hospitals are under pressure to adopt more energy-efficient solutions, such as solar panels, LED lighting, and frequency-controlled drives. While beneficial, these technologies introduce new challenges.

Impact on Power Quality

Energy-efficient devices and advanced medical equipment contribute to power grid pollution, which in turn affects power quality. Ironically, many of these devices are also highly sensitive to the very disturbances they create. This has serious implications for the stability and reliability of the electrical supply, including:

- Increased risk of installation failures due to voltage dips or power surges

- Malfunction of emergency systems caused by capacitive networks, harmonic distortion, and imbalanced phases

- Higher failure rates and maintenance costs due to grid pollution from mechanical systems, medical devices, LED lighting, and solar installations

- Overloaded neutral conductors caused by phase imbalance and power quality issues

- Heavier transformer loads due to network pollution and asymmetrical power demand

- A tightening regulatory framework and growing accountability regarding electrical energy quality

The Consequences of Poor Power Quality

These developments lead to reduced control over electrical power systems. Failures during emergency power operation, voltage dips, and instability can disrupt hospital processes, sometimes even forcing temporary closures of departments. Often, the financial consequences of poor power quality remain hidden, absorbed into maintenance budgets rather than addressed at their root.

Power Quality: A crucial element in healthcare energy management

Existing energy management systems in care facilities are often integrated with building management systems and primarily focus on energy consumption. As a result, the “health” of the electrical supply and voltage often goes unnoticed. Electrical disturbances and issues with power quality are typically not recorded, meaning the causes of power outages frequently remain unknown. For modern healthcare facilities, this is no longer acceptable.

fortop brings its extensive expertise in critical environments, such as data centres and hospitals, to enhance the availability and stability of electrical power under all conditions. To achieve this, fortop employs a unique chain of competencies: measure, analyse, and improve. measure, analyse and improve.

This integrated approach, known as power management, significantly enhances the reliability and continuity of electrical energy supply—key factors in maintaining operational resilience in healthcare settings.

Discover more about ensuring a reliable power supply.

The four aspects of power management

Power management is a continuous improvement process focused on measuring, analysing, and optimising electrical systems. Its goals are to prevent failures, reduce energy and maintenance costs, and minimise the impact of electrical disturbances.

Power management encompasses four key aspects:

1. Energy management

Compliance with the mandatory ESOS energy audit and increasingly stringent government regulations demands continuous visibility into energy flows. Making energy usage transparent raises awareness, encourages engagement with energy-saving measures, and provides real-time insight into their effectiveness.

In addition, this visibility enables accurate energy billing for subletting tenants. By monitoring power distribution from the main supply down to individual systems, issues such as energy losses, idle consumers, and metering errors can be quickly identified and addressed.

2. Load management

Facility managers seek to maximise system capacity without physically expanding the electrical infrastructure. During generator operation, understanding available power is crucial to ensure that connected equipment can be safely supported.

However, challenges such as harmonic distortion, low power factor (cos-phi), and unbalanced phases place additional strain on the network. The dynamic behaviour of loads adds further complexity, making real-time data, sometimes down to the millisecond, essential for accurate forecasting and decision-making.

3. Event management

Voltage dips, surges, and other power events can lead to partial or complete failure of electrical installations. Prompt alerts enable faster troubleshooting and reduced downtime.

Capturing these disturbances with a resolution of up to 50 microseconds allows for root cause analysis and informed corrective action. This level of detail supports proactive maintenance and minimises the operational impact of such events.

Read more about analysers for early fault detection.

4. Power Quality management

Maintaining high voltage quality leads to lower maintenance costs, fewer breakdowns, and improved energy efficiency. It also ensures greater transparency and clearer responsibility allocation, vital in the event of equipment failure and potential liability claims.

Adherence to voltage quality standards is particularly important in medical environments, where it determines whether sensitive equipment may be safely connected, and whether warranties remain valid.

When implementing energy monitoring systems for efficiency purposes, it is essential to incorporate voltage and current quality into the measurement framework. This holistic approach ensures not only energy savings, but also operational reliability.

Three steps to lower consumption, lower maintenance costs and fewer failures

Power management is a continuous improvement process of measuring, analysing, and optimising, with the aim of reducing energy consumption, lowering maintenance costs, and minimising the risk of failure.

Step 1: Measuring with power analysers

Continuous, 24/7 monitoring is essential for any effective power management strategy. It enables the identification of trends, the verification of energy-saving measures, and the immediate detection of anomalies or disturbances.

To implement a comprehensive monitoring system, fortop follows a standardised blueprint that assigns the most appropriate measurement device to each level of the electrical installation. fortop utilises high-precision measuring instruments from Janitza, a German manufacturer known for their application in critical and high-performance environments.

Janitza devices offer a sampling resolution of 50 microseconds, ensuring highly accurate readings of voltages and currents. This level of precision allows even the smallest disturbances to be detected and logged.

fortop’s system identifies four measurement levels, each with a corresponding type of meter:

- Level 1: Incoming supply at medium-voltage level → Power quality analysers

- Level 2: Low-voltage side of transformers → Power analysers

- Level 3: Main distribution output fields → Energy analysers

- Level 4: Sub-distribution and end-users → DIN-rail consumption meters

Janitza offers tailored measuring solutions for each level, ensuring full visibility and control across the entire electrical infrastructure.

The choice of an energy meter depends on what you want to measure and how you want the data to be presented.

Step 2: Monitoring and reporting with DCEM

DCEM Healthcare Edition has been specifically developed to consolidate all measurement data from hospitals and care institutions into a single, integrated system. This software package is tailored to the unique characteristics and demands of electrical installations in healthcare environments.

DCEM offers millisecond-level visibility into both real-time and historical data across the entire installation. It collects input from measuring instruments, switches, and uninterruptible power supplies (UPSs), transforming it into live alerts, visualisations, and comprehensive reports. This information is accessible through a user-friendly web interface on any device equipped with a standard web browser.

The system is infinitely scalable, supporting any number of users, functions, data points, and locations, and has proven its effectiveness in large-scale applications, with networks handling up to 8,000 energy meters.

Alarm manager: preventing failures before they happen

One of the most critical functions within a power management system is the alarm manager. Imminent overloads, voltage disturbances, and deviations in power quality are precisely logged with accurate date and time stamps. Active alarms can be sent instantly via SMS, email, building management system (BMS), or through a dedicated smartphone app, enabling rapid response and minimising downtime.

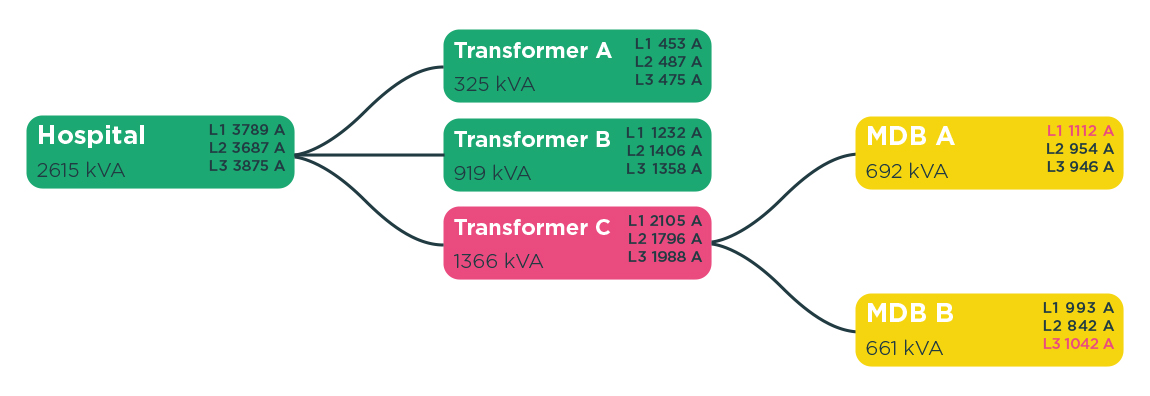

Visualise energy flows with power tree

The power tree feature provides real-time and historical insights into the load on each phase of the electrical system. With a single click, users can identify areas of overcapacity, detect standby equipment, and pinpoint energy-intensive systems. This enables targeted interventions and optimised energy use throughout the facility.

Step 3: Enhancing mains voltage with active solutions

Addressing the root causes of poor power quality is not always straightforward. While individual devices may comply with the relevant standards, their combined effect often exceeds acceptable limits. In dynamic networks, traditional passive solutions, such as power factor correction (cos φ compensation) or passive filters, are typically insufficient. In these modern electrical environments, active compensation systems have proven to be the most effective approach.

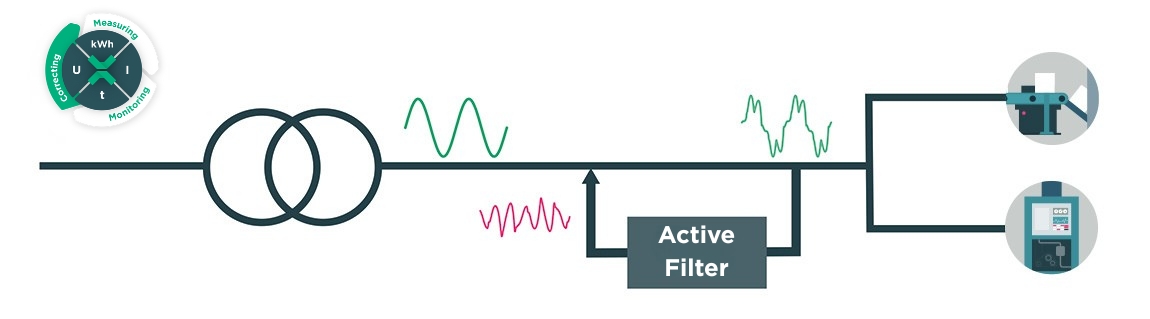

Improve power quality with active filters

Active filters offer an advanced and reliable solution for resolving the most common power quality issues in today’s electrical grids. Their operation can be likened to noise-cancelling technology: by injecting a counter-current that is phase-shifted by 180 degrees, active filters effectively neutralise unwanted electrical disturbances.

This approach enables the resolution of a wide range of power quality problems, including:

- Emergency power system failures due to capacitive networks, harmonic distortion, or unbalanced loads

- Increased system failures and maintenance costs caused by escalating levels of electrical pollution

- Overloaded neutral conductors resulting from unbalanced phase loads and harmonic currents

- Overstressed transformers due to asymmetrical loads and harmonic interference

- Non-compliance with minimum voltage quality standards, which may result in legal or liability issues, especially in healthcare environments

Prevent voltage dips with stabilisation systems

Voltage stabilisation systems are designed to “bridge” short-term voltage dips. Unlike UPS systems, which operate in series with the load, stabilisation systems work in parallel, enabling them to compensate for brief disturbances without interrupting power supply. This not only prevents equipment shutdowns but also avoids damaging power surges when normal voltage resumes.

All from one source

fortop has a team of technical specialists who can guide you through all the steps of power management. From choosing the right meters at each level to commissioning and maintaining software and active compensation systems.