Power Management indispensable in modern electrical installation

Technical managers of electrical installations face major challenges. Numerous energy-saving measures must be taken. In addition, the increase in the use of frequency converters and LED lighting makes the electricity grid increasingly sensitive. This puts increasing pressure on the stability of the electrical installation.

Electrical power supply in industrial plants

The use of electronics in industry has increased enormously in recent decades. Production processes have been automated to a large extent, which greatly increases productivity. It is impossible to imagine life without the use of frequency regulators. In addition, more and more energy-saving measures must be taken. Examples are the installation of solar panels and LED lighting.

All these electronic devices pollute the power grid nd negatively influence the power quality. At the same time, these devices are increasingly sensitive to the pollution they cause themselves. This has major consequences for the stability of the electrical energy supply:

- there is an increased risk of failure of (parts of) the installation due to due to voltage dips and/or power peaks;;

- Failure of emergency operation, harmonic pollution and unevenly loaded phases;

- more failures and higher maintenance costs due to increasing grid pollution caused by frequency converters, LED lighting, solar panels and charging points for electric vehicles;

- a more heavily loaded transformer as a result of grid pollution;

- an increasingly strict legal framework and definition of responsibilities with regard to the quality of electrical energy

One consequence of the above trends is that the manageability of electrical power systems is decreasing. Systems fail in emergency power mode and voltage dips lead to process breakdowns or even the temporary closure of departments. The costs of poor power quality are not always visible and are often paid for from maintenance budgets.

Quality aspects of voltage and current in energy management systems

Existing energy measurement systems focus mainly on energy consumption. Hereby the "health" of power and voltage is lost from sight. Electrical disturbances, voltage dips and power quality are usually not recorded, which means that the cause of power outages is often unknown. This is no longer acceptable today.

With our experience in critical applications such as hospitals, process industries and data centres, we are able to increase the availability of voltage and power under all conditions. Fortop uses the unique chain of competences of measuring, monitoring and improvement for this. This chain of competencies contributes to a higher reliability and continuity of electrical energy and is also called power management. Read more about a good power supply.

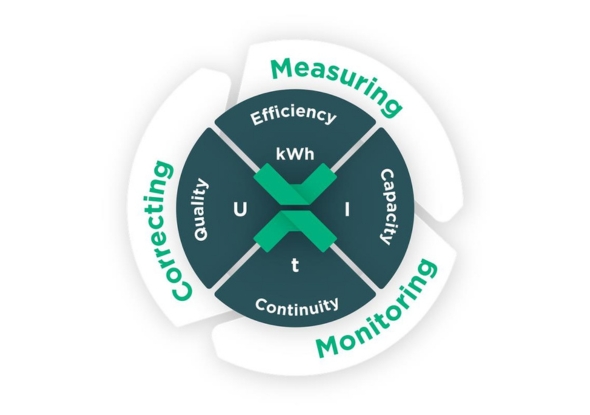

The four aspects of power management

Power management is a continuous improvement process of measuring, monitoring and improving with the aim of preventing failures, reducing energy and maintenance costs and minimising the consequences of failures.

Power management can be divided into four aspects:

1. Energy (kWh)

The mandatory EED energy audit and stricter government requirements necessitate continuous insight into the energy flows necessary. Making energy visible increases awareness and involvement in measures, and provides continuous insight into their effects. It also makes it possible to allocate energy to sub-processes and even products. By visualising the power from top to bottom in the installation, energy losses, standby consumers and connection errors of meters are immediately recognised.

2. Load (kVA)

Managers want to know where growth in the installation is possible, without expanding the installation. How much can I still grow on the existing mains transformer? Harmonic pollution, low cos-phi and unevenly loaded phases put additional strain on the electrical infrastructure. In addition, the dynamic behaviour of the load makes it difficult to make predictions. A good measurement of harmonics and insight down to the millisecond is then necessary.

3. Events (voltage dips and peaks)

With electronic loads such as frequency converters, a voltage drop leads to a current surge. This can cause safety devices to switch off. Events such as voltage dips and current peaks can lead to failure of (parts of) the electrical installation. Timely alarms can reduce downtime by speeding up the search for faults. By registering these dips and peaks to a resolution of 50 microseconds, the cause can be determined and appropriate measures can be taken to minimise the negative consequences of these phenomena.

4. Power Quality

A "healthy" voltage leads to lower maintenance costs, helps prevent breakdowns and saves electrical energy. It also provides insight and a clear division of responsibilities. This is important in liability issues after equipment failure. Voltage quality standards play an important role here. Among other things, it determines whether equipment may be connected and whether or not it is covered by a warranty.

When integrating energy measurement systems for energy saving purposes, it is a must to include and integrate the quality aspects of voltage and current in the measurement concept.

3 steps to lower consumption, lower maintenance costs and less downtime

Power Management is a continuous improvement process of measuring, monitoring and improving with the aim of reducing energy consumption and maintenance costs, and minimising the risk of failure.

Step 1: Measuring

For a continuous improvement process it is necessary to measure 24/7. Only in this way can trends be recorded, energy savings demonstrated and an immediate alarm triggered in case of incidents.

In order to set up a measurement system that covers the entire installation, Fortop uses a standard blueprint in which each level of the electrical installation is given the most suitable measurement instrument. Fortop uses measuring instruments from Janitza for this. Voltages and currents are sampled with a resolution of 50us. This ensures accurate measurement and fault recording. The Janitza meters are produced in Germany and used in many high-end applications.

We distinguish four measurement levels, each with its own measurement instrument:

- Level 1: Incoming fields at medium voltage level; Power Quality Analysers

- Level 2: Low voltage side transformers; Power Analysers

- Level 3: Output fields main distributors; Universal measuring devices

- Level 4: Subdistributors and end-users; DIN-rail verbruiksmeters

Janitza has a suitable measuring instrument for every level.

The choice of an energy meter depends on what you want to measure and how you want the data to be presented. Read more about help choosing the right meter.

Step 2: Monitoring

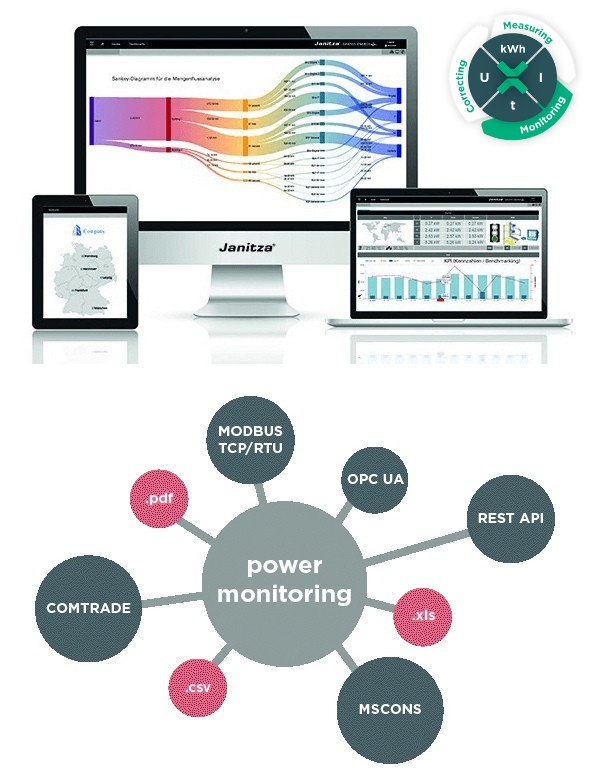

Power monitoring system

A power monitoring system is required to collect all measurement data in one system. A power monitoring system is specially designed to be able to store the large quantities of data generated by the energy meters and convert them into meaningful information. All measuring instruments are eventually connected to an Ether network, after which they are linked to a power monitoring system.

Data via web-interface

A power monitoring system provides millisecond-by-millisecond insight into real-time and historical measurement data of the entire installation. Energy management according to ISO500001, power quality management and RCM (earth fault monitoring) are integrated into one software tool. Data from all measuring instruments are converted into real-time alarms, visualisations and reports. This information is accessible via a user-friendly web interface on all devices with a standard web browser. From the power monitoring system, various links can be made with other systems.

Delivery, commissioning and maintenance

Our engineers are specialists in measurement technology, software and network systems. We have more than 10 years of experience in implementing various types of power management systems at large international companies. We put the systems into operation, maintain them and ensure that periodic updates are carried out. So you are always assured of a working monitoring system.

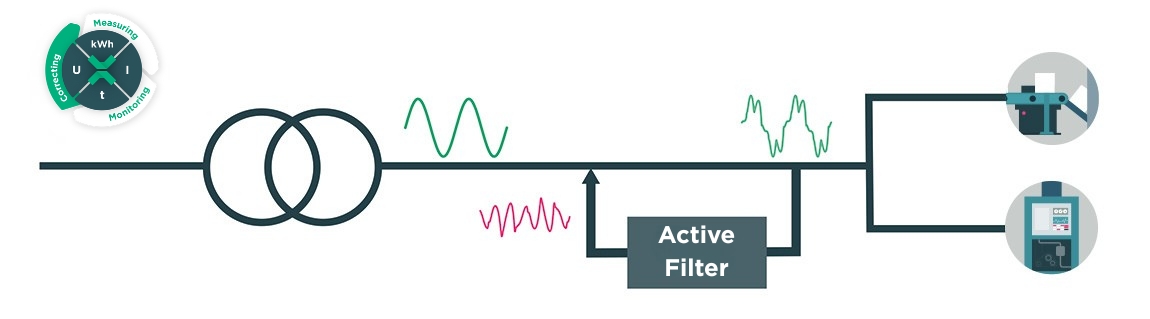

Step 3: Improving the mains voltage through active solutions

Solving the problem at the source is not always easy. Individually, polluting equipment complies with the applicable standards, but collectively, the standard is exceeded. Passive solutions such as cos-phi compensation do not offer a solution in dynamic networks. In modern networks, modern active compensation systems often prove to be the most effective solution.

Improve power quality by applying active filters

Active filters are the ideal solution for solving the most common problems in modern power grids. The operation of an active filter can best be compared to an anti-noise system. A counter-current is injected which is shifted 180 degrees in phase with the current to be cancelled. This makes it possible to solve almost all common power quality problems.

Possible power quality problems

- Failure of emergency power operations due to capacitive grid, harmonic pollution and unevenly loaded phases

- more failures and higher maintenance costs due to increasing grid pollution

- heavier loads on the neutral conductor due to unevenly loaded phases and grid pollution

- heavier loads on the transformer due to mains pollution and asymmetrical load

- non-compliance with the minimum voltage quality standard in hospitals, leading to potential liability issues

Elimination of voltage dips by application of voltage stabilisation systems

Voltage stabilisation systems are solutions for "filling" voltage dips. Unlike UPSs, these stabilisation systems are parallel to the load and can therefore cope with short-term voltage dips. This prevents unwanted power peaks and equipment failures.

All from one source

Fortop has a team of technical specialists who can guide you through all the steps of power management. From choosing the right meters at every level to commissioning and maintaining software and active compensation systems.