Wireless network with sensors and switches - steute nexy

With nexy, Steute offers a wireless Industry 4.0 sensor network solution for industry and intralogistics. Intralogistics optimizes the internal material flow in industry and logistics. Steute has been developing wireless switches for more than ten years. To date, these switches send their status/signal via a point-to-point connection with a LAN Gateway receiver to a higher system.

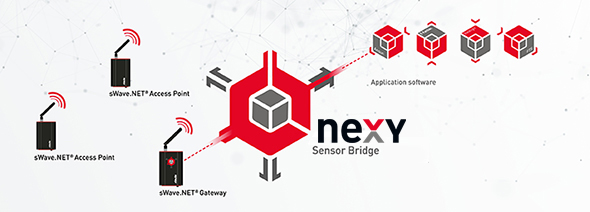

Wireless network with access points

Steute has developed a completely new wireless network with "access points" - steute nexy. With the use of steute nexy, continuous communication between wireless switches and the ERP system or other overlying system is possible. Up to 100 wireless switches can be connected to one access point. With the intelligent Internet of Things (IoT) communication network (nexy) you are able to automate production processes and reduce production costs.

Unique features steute nexy:

- Industry 4.0

- Efficient process and factory performance

- Fast and uninterrupted process optimization

- Universally applicable

- 100% integrated

What is Nexy?

Benefits wireless sensor network

Efficient process and factory performance

With the implementation of the wireless sensor network - steute nexy - you are able to streamline your production processes. Increase the success and productivity of your business in a sustainable way by:

- shorten the time required to supplement materials and components;

- reducing the stock of materials and parts

- avoid overcapacity and surpluses of parts.

Optimize your processes and reduce the costs for intralogistics by making the availability of materials and components transparent and accessible and digitizing order forms/question messages.

Fast and uninterrupted process optimization

Create optimum flexibility when designing and adjusting your production processes. Use a wireless network that is easy to manage, rather than an expensive wired solution. Your processes can be adapted to new cycles or lead times in an instant.

With a flexible production process, you are able to respond adequately to changes in variants, without having to interrupt current processes. Expanding your current production process with additional components for your wireless system can be done at any time so that the installation time is reduced to a minimum with an adjustment.

Can be used universally and 100% integrated

For your wireless lean management processes, a continuous data flow is required from the work floor to the planning and management levels. Seamlessly integrate data from the workplace into existing IT systems such as MES or ERP and adjust it to your needs at any time with the sWave.NET® Sensor Bridge control software. Wireless sensor network systems can be operated in parallel with other wireless networks without interference and can, therefore, be built universally (afterward).

Intelligent precision through systematic networking

Monitor, control and maintain a continuous overview of your production processes based on accurate real-time data and information. Benefit from the high performance of network systems and permanently reliable integration of all sensor data. Improve the quality of your information processes and avoid expensive waiting times or downtime in production - for example, due to transmission errors, cable breaks or other sources of error.

Solutions with wireless sensor network

Whether it concerns eKanban or Andon systems, stack light or AGV applications: digitization makes major changes possible in industrial production processes and offers many opportunities for optimization. To be able to make full use, steute offers an intelligent Nexy solution that makes it possible to integrate your process data into your IT infrastructure reliably and in real-time and thus make it universally applicable. Thanks to the modular structure of the wireless sensor network system, various high-quality components can be connected to each other individually and even used multiple times. Depending on your needs, a wide range of applications can be implemented efficiently and cost-effectively.

Once switched to Steute Nexy, wired systems are no longer needed, maintenance is limited and it is reliable, real-time and robust.

Wireless sensor network solutions:

- Material supply using the eKanban system

- Monitoring of fast flowing materials

- Mobile eKanban rack with AGV system

- "Wake-up" function for AGV in deep sleep mode - saving energy

- Automated transport of goods to AGV

- Andon mobile systems

Receiver for integrating signal towers into wireless systems

The RF UBR device (universal bidirectional receiver) facilitates the activation of existing or new signal towers from different manufacturers. This means that operators of machines and installations can receive information from an ERP, warehouse management or eKanban system, for example. In addition, the receiver can be used for real-time monitoring and data analysis in production, assembly and intralogistics.

The RF UBR is available with 24 VDC or 85 - 230 VAC power supply. With the latest version, users can fully power a signal tower via the wireless receiver - without the need for an external power supply. The wireless connection is the industry-compatible and internationally deployed sWave.NET wireless protocol. Read more about the RF UBR.

Wireless laser sensors for material stock detection

The RF 96 SDS-NET wireless laser sensor is a very suitable solution for detecting and monitoring material supplies, allowing the user to achieve complete material monitoring in production, assembly and/or warehouse.

The RF 96 SDS-NET laser sensor has a compact design and is equipped with a wireless sWave.net module. Integration and mounting in wireless sWave.NET systems is therefore easy and fast, even in confined spaces.

Components for wireless network solution

To get the most out of a wireless network solution for your production logistics, the right components are needed in the right combination. Both the total system and the individual components must meet the highest requirements in terms of reliability and flexibility. That is why we rely on standardized wireless technologies that can be used for different applications and have already proven their reliability in production halls.

Fortop has a wide range of high-quality wireless switches and sensors, certified international standards. By using plug and play modules, the data from switches and sensors are seamlessly integrated into existing IT systems. The steute wireless sensor network also offers the solution for customer-specific applications.

Software for setting up a wireless sensor network

eKanban software

The eKanban software of the wireless sensor network system digitizes, creates networks and automates your Kanban processes. By applying different switches, sensors and access points you are able to eliminate the disadvantages of manual Kanban processes. In addition, the software system is able to make automated bookings in your IT system. The components from the wireless sensor network in combination with your (current) ERP system ensure real-time and without manual input the need for material in your production process.

Features e-kanban software:

- Integration and system adjustment to the wishes and needs of the customer

- Link with SAP via IDocs or RFC available

- Graphic control station with real-time data

- Automated reporting in case of errors / bottlenecks

- Reporting via KPIs (evaluations and statistics for optimal evaluation of your material flows)

Application of eKanban software

The planning and control of Kanban control circuits and production processes can be integrated flexibly and can be adapted to the wishes and needs of a specific application or to the unique production process of the relevant customer. The eKanban software is provided with a simple and user-friendly interface.

The control circuits, kanbans and batch sizes are stored in the software and are linked to the wireless switches and sensors from the entire Nexy system. As soon as a bin is removed from the kanban rack, this is registered by, for example, an optical sensor. The software system registers this action and takes action based on underlying logic, for example notification to the material management for supplementing the kanban rack. The "line runner" receives a digital order on the ekanban application and can, in turn, take action, supplementing the kanban rack. The replenishment of the kanban rack is confirmed by an operator in the nexy application or by a wireless sensor.

All actions, events and processes are visualized on a dashboard for the customer. The dashboard can be configured to your own wishes and needs. The customer decides for himself which tasks, control circuits or materials are shown on the dashboard.