Blue light sensors and photocells

In industry, parts that need to be detected are increasingly designed in a way that makes detection difficult, such as dark, shiny, and curved surfaces or dark and ultra-reflective materials. This poses significant challenges for conventional red light sensors. However, BlueLight sensors offer a significant improvement in reliable detection.

What is blue light?

Blue light, a part of the visible light spectrum with a shorter wavelength and higher energy, is ideal for optical sensors in combination with innovative BlueLight technology. Detecting transparent or black objects can be challenging due to reflection and absorption of light. SensoPart Blue Light offers a solution in these situations, particularly for critical applications. The Blue Light sensor, which does not require a reflector, has a detection range of 2 to 1200 mm and a protection rating up to IP69K. These sensors are available with fixed focus, adjustable via IO-Link or a potentiometer.

Table summarising blue light sensors

| Overview Blue light sensors | |||||

|

|

|

|

|

|

| Technical information | |||||

| Product type | FT 10-BF2 / BF3 | FT 25-BF2 | FT 25-BH | FT 50-BH | FT 55-BH |

| Type of light source | LED, blue 450 nm | LED, blue 450 nm | LED, blue 450 nm | LED, blue 450 nm | LED, blue 450 nm |

| Setting | Fixed focus | Fixed focus | Adjustable, IO-Link | Adjustable, potentiometer | Adjustable, potentiometer |

| Range/switching distance | 2…30 mm / 2…50 mm | 0…80 mm | 0…200 mm | 2…300 mm | 3…1200 mm |

| Specifications and datasheets | |||||

| View | View | View | View | View | |

What is BlueLight technology?

Objects are often considered difficult to detect if they reflect little or no light back to the receiver. This includes, for example, dark, glossy, transparent parts or objects that are at a strong angle to the sensor.

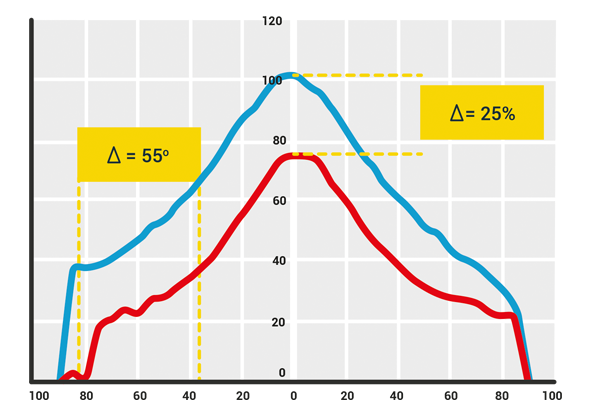

The reason for the more reliable detection of BlueLight is the higher intensity on the surface of the object to be detected. The penetration depth of short-wave blue light is lower than that of red light, which means more light returns to the sensor. This is especially true for dark, glossy, curved, and even transparent surfaces.

Red light sensors are used in many applications in industrial automation. However, ordinary red light sensors reach their limits when it comes to detecting difficult surfaces, often resulting in many - potentially very costly - errors that go unnoticed until it is too late. In addition, their process stability decreases at strong angles to the sensor.

BlueLight sensors can handle multiple problems at once, such as black objects with a high-gloss surface at a shallow detection angle. But perhaps most impressively, their high precision in suppressing very bright or reflective backgrounds makes them an essential solution for many industrial applications.

Video: Detection of different materials

What problem in the market was solved by this technology?

The emergence of BlueLight sensors can be traced back to 2014, when SensoPart was tasked with detecting solar cells in solar panels. The nature of these silicon cells is to absorb as much light as possible, making them practically undetectable by traditional red light sensors. The SensoPart team discovered that detecting the dark blue solar cells with a blue light sensor worked much more reliably, as the solar cells have a higher reflectivity in the blue range. Object detection with blue light was born.

It soon became clear that all industries could benefit from this new technology, as sensors in many automated processes need to reliably detect deep black, reflective, curved, angled, glossy, and transparent objects. In addition, it was discovered that blue light sensors even reliably detect under large angles relative to the object, which is often the case with limited installation space.

Today, BlueLight sensors can easily be used as the new standard, as they enable significantly higher process reliability than red light sensors in detecting demanding materials.

Detecting different surfaces

|

|

|

||

|

Detection of very dark objects |

|

Reliable detection of reflective surfaces |

|

Detection of transparent objects |

What are the advantages of BlueLight?

BlueLight sensors can handle multiple challenges at once, such as detecting black objects with a highly glossy surface at a shallow detection angle. But perhaps most impressive is their high precision in suppressing very bright or reflective backgrounds, making them an essential solution for many industrial applications.

- Process reliability: BlueLight sensors can reliably detect difficult surfaces: deep black, reflective, curved, placed at an angle, glossy, and transparent surfaces.

- Robustness: Even when BlueLight sensors are laterally mounted at a strong angle to save space, they still provide high process stability.

- Flexibility: If the objects to be detected in a system change, BlueLight sensors offer the highest flexibility in critical object detection.

- Warehouse optimization: BlueLight sensors solve both standard and problem applications, allowing red light sensors to be omitted to save space.

What types of industries benefit from BlueLight technology?

BlueLight sensors solve a wide range of applications and can therefore be successfully used in many different fields. In the automotive industry, the share of difficult surfaces is very high. Potentially critical plastic and metal parts, from matte black door frames to high-gloss round gearshifts, all need to be reliably detected. The sensors also provide highly reliable detection of transparent objects, such as bottles and packaging films for the food industry, as well as sample tubes, syringes, and pipette tips for the pharmaceutical industry.

Typical industries:

- Automotive: Detection of metals and strongly light-absorbing components

- Packaging: Detection of transparent films/containers/bottles and labels

- Pharmaceutical: Presence and positioning of glossy blister packaging

- Solar energy: Detection of presence and position of wafers

|

|

|

|

| Automotive | Packaging | Pharmaceutical | Solar |

What types of objects require reliable and accurate object detection?

Reliable object detection is crucial in many production processes. Parts with different shapes, colors, and textures need to be detected, transported, sorted, gripped, and assembled. In recent years, photoelectric diffuse sensors with blue-emitting LEDs are increasingly being used in such applications. BlueLight sensors have proven to be true all-rounders, especially in the detection of challenging parts.

In the automotive industry, for example, this could be metal and highly light-absorbing components. For packaging, this could be transparent films/containers/bottles and labels. The pharmaceutical industry needs to detect the presence and positioning of glossy blister packs, and for solar energy, it could be the presence and position of wafers.

Materials that are difficult to detect

Detecting objects with difficult or demanding materials is a real challenge for a number of industries. When red light sensors reach their limits, conventional solutions usually require investments in additional photoelectric or ultrasonic sensors.

If sufficient process stability cannot be achieved with red light, diffuse sensors with BlueLight technology can be an alternative. This is because the reflective properties of blue light can be used to significantly improve reliable detection of critical materials, from metals, dark or light-absorbing components to curved, shiny, and transparent objects.

Detecting dark, black and shiny objects

While transparent objects absorb little light, black and dark objects absorb the opposite. Detecting dark textiles, shiny black surfaces, LCD screens and other light absorbing objects is a huge task for red light sensors. SensoPart's blue light sensor detects these materials easily and reliably.

Watch the video on how to detect dark and shiny objects.

Detection of transparent objects

Detecting, counting and positioning transparent objects is soon a bridge too far for conventional photocells. Transparent objects such as glass and plastic only absorb a small part of the light and also cause a small difference between the transmitted light and the reflected light in the receiver. It is then an enormous challenge to transmit a stable and clear signal, for example, to automate a bottle filling line.

Watch the video below about detecting transparent objects.

Objects and materials that are difficult to detect

The blue light sensor offers a solution even for materials or objects that are very difficult to detect. Examples are the detection of drops of water, glass objects, transparent foils, highly reflective materials such as magnets and polished metals, mirrors and uneven surfaces. The blue light sensor detects these materials without any problems.

Application example: Detection of screws in the supply

The amount of screws required for the assembly of the battery packs is stored in a bunker supply system and individually fed to the screw systems from there. For later verification of the correct position of the screws, they need to be detected at a specific position in the supply system to provide a trigger signal.

The challenge

The reflective material and surface structure make it difficult to detect the screws in the bunker supply system. Additionally, a certain distance to the transport line must be maintained despite the limited installation space.

Our solution

The FT 10-BH(D) subminiature sensor with BlueLight technology can be integrated anywhere thanks to its compact design, yet it is just as powerful as sensors from larger series. Reflective, transparent, or absorbing surfaces pose no obstacle for this sensor. Compared to inductive sensors, it offers a large scanning range. The simple operating concept makes its installation easier. It is sufficient to manually or digitally select the respective screw and the background directly on the sensor and teach this distance. In addition, settings can be easily executed via the controller thanks to IO-Link.

Your benefits

- Reliable detection of small screws

- Improvement of assembly process efficiency

- Reduction of downtime and production costs

- Easy operation and configuration

- No reflector needed for detection of reflective surfaces

Comparison between red and BlueLight sensors

The difference between red and BlueLight sensors lies in the wavelength. Red light sensors use red light, which has a long wavelength. BlueLight sensors use short-wavelength blue-violet light. Because the wavelengths have different properties, the two types of sensors must be considered separately for each application.

It is important to note that red light sensors reach their limits when detecting difficult surfaces such as dark, highly reflective, angled, curved or transparent materials. In addition, their process stability decreases at strong angles of incidence.

This is exactly where BlueLight sensors excel. Short-wavelength blue light is less absorbed or reflected, providing high process stability even with challenging materials and surfaces, even at strong angles of incidence. Moreover, they are flexible in use and can detect critical and non-critical objects, allowing them to replace red light sensors if necessary, saving space and costs.

When is BlueLight the ideal choice?

It's a matter of "what you can do, I can do better". Not only can BlueLight sensors perform all the tasks of red light sensors, but they are also perfect for a number of additional scenarios. In addition to reliable detection with challenging surfaces, as mentioned above, the superior reflective properties of BlueLight are effective at stronger angles of incidence, and also offer adjustable background suppression for very bright or busy environments.

Below, we explore three scenarios where red light and BlueLight sensors can solve the same applications.

Scenario a: Fill quantity monitoring with a red light sensor

The challenge

During the assembly of a battery pack, many screws are processed. To prevent interruptions, it is important to be alerted when the screws need to be refilled. The sensor should not hinder the handling area, and it is further complicated by the reflective stainless steel body of the storage bin and the transparent filling valve.

The solution

This is a good example of a situation where a BlueLight sensor can perform the same task as a red light sensor in detecting when a predetermined level of screws has been reached. Both systems are equally effective in solving this application.

Scenario b: Detection of plates with a red light sensor

The challenge

Another task in industrial automation is the detection of plates using optical sensors. The surface properties of some plates can pose a problem, as they can be very bright white and also highly reflective. This is further complicated by the constant movement of the conveyor belt.

The solution

The bright white and reflective plates can be reliably detected using either red light sensors or BlueLight sensors. Both the red and blue LEDs provide high process stability, even with these challenging bright white surfaces.

Scenario c: Detection of plates in the robot gripper with a red light sensor

The challenge

A related task to scenario b above is the industrial automation required to detect and grip plates using a robot and optical sensor. The sensors must monitor the presence of the plates in the robot gripper, which is made more difficult by the highly bright white and glossy surface of the plates.

The solution

Both the red light sensors and the blue light sensors can reliably detect the bright plates in the robot gripper. Once again, both the red and blue-emitting LEDs enable high process stability, even when space is limited and the sensor is mounted on the robot gripper.

An overview of detecting dark objects

Automated production has evolved significantly over the past decades, with more and more companies relying on BlueLight sensors to detect and assist in transporting, sorting, gripping, and assembling objects.

But why BlueLight? The secret lies in different wavelengths. Unlike red light, the light from blue LEDs has a much shorter wavelength, which means it does not penetrate as deep into the surface of objects. This means that the sensor beam reflects more easily, allowing dark, muted, shiny, and reflective objects to be easily detected, even at strong angles of incidence. And with the increasing prevalence of these critical components, especially in the automotive industry, BlueLight sensors dramatically improve detection and process stability on the assembly line.

Object detection with a reflection-optical sensor is based on detecting and analyzing light signals that are reflected and emitted by an object.

The process can be divided into the following three steps:

Step 1 |

Step 2 |

Step 3 |

| Light Projection | Reflection | Localization |

| The sensor emits light that hits the object. | Light is reflected by the target object and returns to the sensor where it can be detected and interpreted by the sensor's receiver. | The change in the amount of light is detected by the sensor and the position of the light spot on the receiving element determines the position of the object. |

Object detection process

|

|

|

||

|

Detecting objects at an angle |

|

Detection of panel components |

|

Dark objects |

| When a beam of light hits an object at a shallow angle, or a surface that slopes away, very little light will reflect back, making the object harder to detect. Here, blue light provides greater reflectivity, increasing the amount of reflected light. | Dark and muted colours are becoming increasingly prevalent in the automotive industry, especially in vehicle interiors. These deep black and glossy surfaces can pose problems for conventional red-light sensors. But sensors with blue-emitting LEDs can significantly improve object detection. | By nature, dark objects appear dark because they don't reflect much light. Receiving reflected light from them is already difficult. Here, the shorter wavelength of blue light resists absorption to enable more reliable detection. |

.png)

BlueLight technology solves challenging application problems

It's not an exaggeration to say that BlueLight technology has significantly improved the recognition of dark objects. SensoPart has further advanced this technology by optimizing the transmitter and receiver components in their BlueLight sensors for even better detection results. The outcomes are not only more reliable and robust, but also address various challenges and problems associated with red light detection.

Detection of incomplete clips for car door panels

In the automotive industry, clips are used to connect the side trim of the car door to the door itself.

If the clips are not fully assembled, they can cause unwanted noise or even come loose entirely. Therefore, the clips must be checked for completeness. A BlueLight photoelectric diffuse sensor with background suppression allows for reliable detection regardless of the shape, color, and texture of the clips. And thanks to the precisely adjustable background suppression, the sensor only detects the desired part of the clip.

Detection of defective parts during injection molding

When producing dark plastic parts using injection molding, some parts may be under-molded or not molded at all. To remove these rejected parts, an optical sensor must reliably detect dark and deep black objects. With a BlueLight photoelectric diffuse sensor with background suppression, the reliability of detecting these highly light-absorbing objects can be significantly increased. Limited installation space poses no challenge as the compact, robust housing is perfectly suited for use directly in the robot gripper.

Detecting dark objects on a moving conveyor

Producing a car door involves using various dark and glossy door seals. To ensure these seals are positioned correctly, they are fed over a conveyor belt. During transport, the end of the seal must be detected so it can be positioned correctly. Thanks to background suppression, a photoelectric diffuse sensor with blue light can reliably detect these dark objects and send a signal to the conveyor to stop the seal in the correct position, allowing the part to smoothly move to the next production step.

Condensation on sensor due to temperature difference

A chicken supplier had problems detecting the transparent trays in which the chickens are transported. The processing hall is a cool and humid environment, which causes condensation on the sensor. Because of this, the sensor with reflector used could not make a good detection.

The customer suggested using a fibre sensor from another supplier. After testing, the desired switching distance (30 cm) turned out not to be achievable with this sensor.

The Blue Light sensor FT 55-BH from SensoPart solved the problem. The transparent dishes are perfectly detected and by working with a sensor without reflector, cleaning of the sensor is no longer (or to a lesser extent) necessary. The sensor is IP69K, which is desirable in chicken processing to meet the hygienic requirements.

More photocells and sensors from SensoPart

Read more about photocells and sensors from SensoPart: