ATEX switches & sensors - steute Extreme

Environmental conditions have a major impact on the durability and functionality of switchgear such as footswitches, position switches and pull-wire switches. Extreme heat or cold, dust, humidity, water, indoor or outdoor use, explosion and corrosion resistance - there are many conditions where standard switchgear will not work or will cause undesirable faults.

Areas of application steute Extreme:

|

|

The 4 ingredients for an extremely good product

What makes steute Extreme?

The combination of properties makes steute Extreme and unique. They are standard products which have been adapted to function safely and reliably in extreme conditions. For example, magnetic switches which, in addition to an IP69 sealing degree, are also Ex certified, have a corrosion-resistant housing and can withstand temperatures of up to -60 degrees Celsius.

Automation and Extreme

| ES 95 W | Position switch with safety function | EX ES 97 W | Ex Position switch with safety function |

|

|

|

|

Sealing degree IP65 - IP69K

The IP value of switchgear determines the value of protection against solids and liquids. Switchgear with an IP65 protection rating is resistant to water jets, for example when cleaned with a standard water hose. Switchgear with an IP68 protection rating is water pressure resistant and suitable for use under water. The extreme switches from steute have a protection degree up to IP69K.

What is an IP69K protection degree?

The IP69K sealing degree offers protection against the penetration of dust and water products under high temperature and high pressure. The IP69K sealing degree is ideal for use of equipment in conditions where careful cleaning or frequent flooding of the equipment is required.

Hygiene of paramount importance

In industries such as food processing, where hygiene is of great importance, the equipment must withstand rigorous high-pressure cleaning procedures at high temperatures and with aggressive cleaning agents.

Resistant to dust and dirt

In many industries, where dust and dirt can be a problem, it is important to ensure that no dust can penetrate a product's housing and cause it to malfunction. Steute has many switchgear products that are unique due to the high sealing degree of IP69K. Products with an IP69K sealing degree undergo a challenging series of tests to ensure that they offer protection against water and dust ingress under high pressures and temperatures.

See switches and sensors with IP69K protection degree and read more specifications:

Material housing

The housing of switchgear plays an important role in the service life of the switch, protects against extreme conditions and influences the production process. When switches with a standard housing are used in a demanding environment with extremely high or low temperatures, under water or in humid areas, unwanted problems can arise. These include corrosion or the freezing or melting of switchgear with all its consequences.

The choice of housing material depends on the application. The most commonly used materials are the plastics ABS (Acrylonitrile-Butadiene-Styrene) and PC (polycarbonate) or the metals aluminium and steel. PC is suitable for outdoor use where ABS is less resistant to UV light. Both plastics are lightweight and resistant to chemicals and cleaning agents.

For the extreme applications, glass fibre reinforced thermoplastic (PA66) offers the solution. PA66 has a lower density compared to steel or aluminium, better chemical resistance, lower wear and friction and lower production costs.

When the switches are used in an application with high temperatures, aluminium or metal is preferred. Steute's switchgear has a temperature range of -60°C to +180°C.

Lift limit switch for crane hooks

On cranes and lifts it is necessary for safety to check the upper hook position. This prevents the crane hook striking the boom head when the load is lifted. A special type of lifting limit switch ensures that this is not possible. The limit switch is equipped with a counterweight that keeps the switch closed. As soon as the lifting block reaches the upper end point, it bumps against the counterweight. The counterweight is lifted and causes the contact to open.

Features lift limit switch for crane hooks

The lever end switch is used in harsh conditions and must be resistant to corrosion and, if necessary, to salt sea water and extreme cold (-40°C). The switch must also be insensitive to vibrations and shocks. In addition, for safety reasons, high reliability is fundamental. When used on drilling platforms or gas tankers, there are requirements for explosion protection. The ZS 73 series of steute pull-wire switches are the right solution, suitable for ATEX zones 2D and 2G.

View ZS 73 pull-wire switches (safety) in the Product Portal

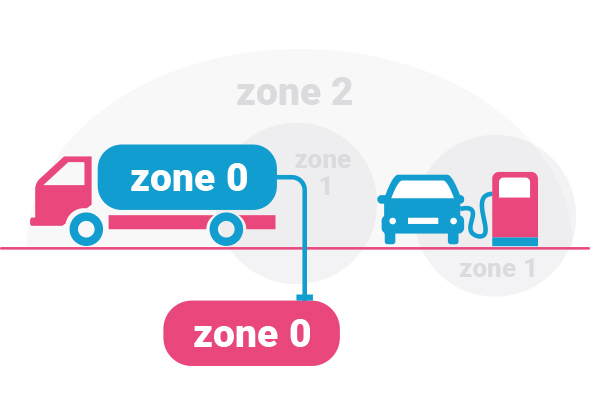

ATEX zones

ATEX stands for all situations where there is a risk of gas or dust explosion. The abbreviation ATEX comes from the French words ATmosphere EXplosible from the European guidelines on explosion safety.

Explosion hazard

Companies that work in environments with an explosion risk must take measures to guarantee the safety of their employees in order to carry out their work. Guidelines have been drawn up for this. Switching devices that are used in environments with an explosion risk have to meet specific requirements.

The housing and sealing degree play an important role in the use of switchgear in ATEX zones. ATEX zones are divided into two areas; gas explosion zone (zone 0, 1 and 2) and dust explosion zone (zone 20, 21 22). The zones are divided as follows:

- Zone 0/20: Frequent or always an explosion hazard present (> 1000 hours per year).

- Zone 1/21: Frequent or occasional danger of explosion (< 1000 and > 100 hours per year)

- Zone 2/22: Little danger of explosion (< 10 hours per year)

Extreme real extreme?!

Most Extreme switches are suitable for use in damp, wet and even salt water environments. Corresponding corrosion tests, for example the salt spray test according to DIN EN ISO 9227, monitor the quality of such switches. But how do these switches perform in practice?

How are they affected, for example, by repeating waves or underwater pollution? These are crucial questions because Extreme switches are often used in maritime applications on ships, on drilling platforms, in quay-anchor systems or at container terminals in seaports.

Steute carries out long-term and thorough tests to ensure the durability of the Exterme products. Read more about these tests in practice.

Extreme Switchgear and Sensors for Shipbuilding and Port Technology

Safe switching under extreme conditions

High or low temperatures, humidity, vibrations, dust, danger of explosion: Where other switching devices fail, steute "Extreme" switches have only just begun. They are designed from the ground up for Extreme application areas such as:

- Hazardous (dust) explosion areas (processing and transport of powdered materials)

- Storage below zero

- Temperature-controlled manufacturing processes

- Hygienic-compatible production and packaging

- Wet areas, e.g. bottling and filling

Magnetic sensors and magnetic proximity switches

In environments with extremely low temperatures, users rely on the non-contact operation of sensors. With non-contact magnetic sensors, there is no danger of frozen moisture interfering with the operation of mechanical switches such as position switches.

Applications of magnetic sensors

The magnetic sensors are ideally suited for detecting the position of valves, covers and other moving parts, for example, for installations in the oil and gas industry (onshore and offshore), shipbuilding and port facilities.

Features steute magnetic sensors:

- Temperature range: -60 °C to +130 °C

- Protection class IP66 to IP69K

- ATEX and IECEx approved

- Duroplast and stainless steel housing

- Both wired and wireless

Control switch for extreme conditions and explosive atmospheres

The Ex BF-80 series of control switches bear the ATEX/IECEx certificate and are designed for use in potentially explosive environments with a temperature range of -60°C to +65°C. These unique features open up additional application possibilities for explosion-protected control devices, for example in shipbuilding, offshore technology and the oil and gas industry.

Ex BF 80 series housing

The new series is available in three housing sizes for one, two or three control devices. The user can choose between different control elements, indicator lights and key switches. Read more about the Ex BF 80 series of control switches.

Pull cord switch for extreme environments

The ZS 92 S pull-wire switch with safety functions has an aluminium housing and multiple coatings (passivated, base coat, powder coat). The pull-wire switch can withstand temperatures from -40°C to +85°C.

Installation in any work position

The ZS 92 S pull-wire switch is available in nine different settings and can be installed in any working position. Rear mounting is also possible.

Paint on the pull cord switch comes off due to cleaning

At 2 Sisters Storteboom in Nijkerk, the paint on the pull cord safety guards was coming off. Not a desirable situation for a company that has to comply with the strict requirements that apply within the food industry.

Plastic pull-wire switch

"The pull cord protection works fine in itself, but thanks to our cleaning process the yellow colour slowly disappeared. During the day the temperature is between 2 and 4 degrees, but the cleaners spray the work floor and the machines with hot water in the evening. This caused the paint to peel off and disappear into the pits. Naturally, we were looking for a solution to this." Read more about the solution with a plastic pull cord switch.

Foot switch for marine and port technology

To prevent accidental operation, the foot switch has a protective cover. The seawater-proof aluminium housing with corrosion-resistant screws and parts is specially designed for reliable operation at sea and in ports. The footswitch with Ex-protection can be used in gas-Ex zones 1 and 2, but also in dust-Ex zones 21 and 22.

Footswitch offshore application

A typical application for this product is the electromechanical actuation of winches to winch or tension mooring cables in ports. A winch that reels a mooring cable can be started and stopped using a foot switch; a second foot switch can be used to release the mooring hook that is attached to the anchor chain in order to allow the ship to put out to sea or to release the chain quickly. Read more about custom made foot controls.

Extreme position switch - ATEX

The loading systems of a manufacturer of liquid transport systems are used to handle large quantities of petrol, natural gas, liquefied gas or chemicals.

Explosion protection and high temperatures

In addition to explosion protection and machine safety, temperature also plays a role. If, for example, hot liquid tar is to be loaded, the loading arms must be protected from the heat. The switches must therefore be heat-resistant.