What is your Robotic Eye-Q? Smarter automation of vision-guided robotics

In the world of Industry 4.0, where data control is becoming the norm, vision sensors such as the VISOR® Robotic are an important step in the transformation from traditional robots to collaborative robotic systems (cobots). In the manufacturing industry, quality is one of the most important factors. Cameras play an important role in this. Vision sensors from SensoPart serve as the 'eyes' of cobots, which improve production processes and collaborate efficiently with people. They detect defects and irregularities and ensure that only defect-free products leave the production line.

Seamless integration and usability

VISOR® Robotic is known for its ease of use and ability to integrate seamlessly with diverse robotic systems. With various detection options, it offers a solution for a wide range of applications. Thanks to the standardized interfaces and flexible data structures, the sensor is compatible with robots from different manufacturers and can be used in a wide range of industrial processes.

A step ahead of the competition

In today's data-driven world, companies that are able to quickly adapt to change have a competitive advantage. With the vision-guided technology of the VISOR® Robotic, companies can strengthen their production processes, increase efficiency and ultimately increase their Robotic Eye-Q. With the Target Mark 3D technology, the VISOR® Robotic is able to perform complex tasks.

What is Vision Guided Robotics?

Vision-guided robotics represents a new phase in industrial production, where cameras and machine vision systems enable robots to accurately identify and handle objects. This technology has led to a replacement of complex and maintenance-intensive mechanical guides, increasing efficiency and profitability in production processes.

Communicate in the language of the robot

In a world where robots increasingly work together with humans, it is essential that they can react flexibly to changing situations. Vision-guided robot sensors, such as SensoPart's VISOR® Robotic vision camera, provide reliable information in a format that robots understand, allowing them to recognize defined objects or scenes in their environment and respond appropriately.

Integration of applications and libraries

To simplify the integration of the VISOR® vision camera in robot applications, SensoPart has developed software such as the URCap and KUKA app. These enable the robotic vision camera to communicate seamlessly with the robot, increasing efficiency compared to traditional methods. This makes vision-driven robotics a cost-effective and efficient alternative to traditional production methods.

Extra 'eyes' on the robot's gripper

Distance sensors can be used additionally if required: Our range extends from the subminiature sensor FT 10-RLA - the smallest optical distance sensor in the world - to the highly versatile analogue model FT 55-RLAM. This ensures that the robot can always grip parts accurately despite variations in shape and position.

Which industrial robots need a vision system?

|

|

|

||

|

Articulated Arm Robots |

|

Gantry Robots |

|

SCARA Robots |

| These robots are used in mechanical engineering and the automotive industry to execute complex motion sequences. |

These robots are large and robust, enabling them to transport heavy loads over long distances. They are frequently used in logistics and packaging. |

|

These industrial robots, abbreviated as Selective Compliance Assembly Robot Arm, feature a parallel hinge designed for rapid and precise assembly and production processes. |

|

|

|

|

||

|

Delta Robots |

|

Collaborative Robots (Cobots) |

|

Mobile Robots |

|

Light and fast robots that are particularly suitable for packaging tasks due to their flexibility and speed. They have a triangular structure and can move quickly and accurately within a limited workspace. |

|

These collaborative robots work alongside humans to assist with complex tasks that cannot be fully automated. They are used in various fields, including assembly, handling, and inspection. |

|

These Autonomous Mobile Robots (AMRs) move on wheels or tracks. They can be used in various environments and tasks, from factory inspection and maintenance to collecting and delivering goods. You can also mount a second robot on an AMR, eliminating the need for a separate station and making it equally mobile. |

How vision systems work in robotics

Vision systems in robotics work by collecting and analyzing visual information from the robot's environment. For example, they can detect certain objects or determine their position. The sensor then converts this information into commands and signals that the robot can process. In this way, the robot can adapt its actions to the environment and perform specific tasks. To process images, vision systems use techniques such as edge and contour detection, feature extraction and pattern recognition.

Industrial challenges and the limits of traditional robots

Companies considering the move to automated manufacturing systems and robots face challenges around reliability, high initial costs, the need for specialist programming knowledge and the limited adaptability of traditional robots. These factors can hinder production efficiency and slow down the demand for quality, health-conscious and environmentally friendly production solutions.

However, SensoPart's VISOR® Robotic sensor offers an innovative solution: this advanced vision sensor can be seamlessly integrated with leading robotic systems, thanks to specific interface modules that simplify programming and integration. This even enables automation of complex or previously costly tasks, enabling an efficient response to modern production challenges.

Key industries for vision-guided robotics

|

|

|

||

|

Assembly |

|

Material Handling |

|

Packaging |

| Robots can assemble components, such as electronic components on circuit boards. They can determine the precise position and orientation of parts, enabling them to work with high accuracy and speed. |

Robots can recognise and manipulate the size and shape of materials like metal or plastic. This allows them to sort, stack, or place materials, thereby increasing the throughput of production processes. |

|

Robots can package products by recognising the size and shape of the items, placing them in the appropriate packaging or carton. They can also handle product changes quickly and easily, resulting in faster throughput. |

|

|

|

|

||

|

Logistics |

|

Joining |

|

Automotive |

|

Robots can sort packages on conveyor belts or in warehouses. With the ability to react in real-time using cameras and sensors, they can perform well even in a busy workplace, ensuring goods are dispatched on time, every time. |

|

Thanks to their precision and speed, robots can be used for various joining and connection processes, including welding, screwing, soldering, gluing, or riveting components. |

|

Robots enable precise positioning and quicker assembly of body parts. They can also perform leak tests, place battery modules, screw housings, assemble electrical connectors, and much more. |

Choosing the right camera for the robotics system

When choosing a suitable camera for a robot, there are numerous factors to consider. The camera choice can directly impact the robot's performance and the quality of its outcomes.

- Camera Resolution: One of the key factors is the camera resolution (0.5MP to 5MP). Higher resolution enables a robot to discern finer details and execute more precise movements. However, processing high-resolution images might demand more computational power, which could affect the robot's speed of action.

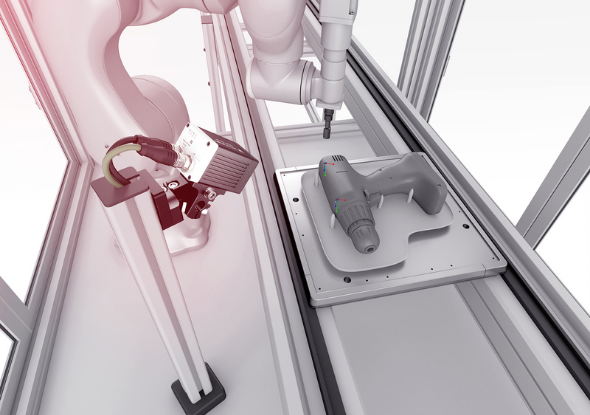

- Design and Concept: Reflect on how the camera will be used. For instance, in end-of-arm tooling applications, the camera is mounted on the robot's gripper arm. Thus, the camera needs to be lightweight and compact to avoid influencing the gripper's weight and ensuring accurate camera positioning.

- Speed: The camera's speed is also a crucial factor. A faster camera enables the robot to make quicker decisions and perform tasks more rapidly. However, excessive speed can also lead to higher computational demands, potentially affecting the robot's performance.

- Camera Type: The camera type can significantly influence the robot's performance. Various camera types must be chosen based on the application's requirements. For example, a colour camera can aid in object identification, while a 3D camera can be useful for distance measurement and generating three-dimensional models of objects.

- Calibration: Accurate calibration of sensors and cameras is vital for robot guidance precision. Schedule regular calibration and maintenance.

- Software: Ensure compatibility of sensors and cameras with the robot control software and the used algorithms for seamless integration and efficient operation.

- Environmental Conditions: Consider your workplace's temperature, dust, humidity, and vibrations when selecting sensors and cameras. Make sure they are suitable for the given conditions.

- Lighting: Good lighting is crucial for image capture quality. Contemplate using LED ring lights, spotlights, or external light sources to ensure even lighting and avoid shadows or reflections.

- Field of View: The camera's field of view and working distance to the object must be considered during the planning phase to ensure adequate image coverage and ample space for robot movements.

Choosing the right camera for a vision-guided robotics system can be a challenging task, as it directly affects the robot's performance and the quality of outcomes. A technical specialist from fortop can assist in selecting the appropriate camera, taking all relevant factors into account, including resolution, sensitivity, speed, camera type, calibration, compatibility, environmental conditions, lighting, and field of view. Through meticulous planning in the initial stages, the fortop technical specialist can ensure that the vision-guided robotics system operates smoothly and achieves optimal results.

How can vision systems improve production processes?

Vision systems can significantly improve manufacturing processes by providing robots with the ability to sense and respond to their environment. This is made possible by advanced cameras and vision software.

Vision systems allow robots to identify components quickly and accurately position and assemble them, improving the efficiency and accuracy of the manufacturing process.

In addition, the flexibility of vision systems ensures rapid adaptation to changing production requirements. With a simple adjustment in the camera software, robots can instantly adapt to new production requirements, making the production line more versatile.

This rapid adaptability, enabled by vision systems, revolutionizes production and makes it possible to produce in an even more efficient and versatile way.

Discover a wide range of possibilities with 2D and 3D applications

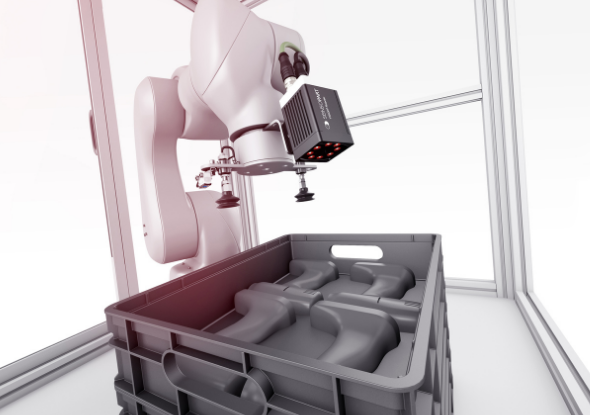

The fusion of the vision sensor and the robot opens up numerous application possibilities in 2D and 3D robot-led contexts. Pick and place applications can be effectively automated using vision-guided robotics. This is exemplified by applications such as feeding and assembling parts in the automotive and supply industries, as well as placing printed circuit boards in electronics manufacturing.

In addition, there are no strict boundaries between 2D and 3D applications. For example, if the robot needs additional height information to pick up stacks of sheets in multiple layers, a specific 3D vision system is not necessarily necessary.

Target Mark 3D function

The Target Mark 3D feature in the VISOR® Robotic enables the robot to interpret and act on highly accurate 3D information and position data. This creates a simple, intelligent, mobile and autonomous working environment. The target marker position is determined only once during the initial camera setup and can then be easily re-learned by any VISOR® Robotic camera. This contributes to time savings, efficiency and precision. Even the smallest deviations in the working position are accurately detected by the Target Mark 3D and corrected effortlessly without the need for reprogramming.

Not just any sensor: the smart machine vision from VISOR® Robotic

The VISOR® Robotic is equipped with several image evaluation algorithms, such as the contour detector and the BLOB detector, which ensure excellent detection accuracy depending on the type of object and the application. The contour detector recognizes the unique shape of an object based on its edges, while the BLOB detector detects irregular shapes through contrasts between foreground and background, such as a loaf of bread on a conveyor belt. Read more about BLOB function.

VISOR® Robotic has special features designed to improve interaction with the robot and simplify the automatic pick-up of detected objects. The grab clearance check ensures that the object has sufficient space in relation to surrounding objects during handling. A pre-programmed gripper offset informs the robot if the object should be picked up at the side rather than in the middle. With these intelligent functions, VISOR® Robotic offers accurate and efficient automation options.

In addition, the VISOR® Robotic is compact, robust and lightweight, and can be used both at rest and in motion, on a robot arm or gripper. In addition, the design can withstand harsh conditions, such as dust or moisture.

Easy to integrate with a variety of connectivity options

The VISOR® Robotic features a range of connectivity options, enabling seamless integration into existing systems. The device supports interface protocols such as sFTP, TCP/IP, EtherNet/IP and Profinet Conformance Class B, for easy connection to PLC or PC systems.

Dedicated apps and modules from manufacturers such as ABB, KUKA, Stäubli and Universal Robots help bridge the gap between machine vision processing and robot control, eliminating the need for manual programming of the communication interface in the robot's control software. The intuitive teach-in function allows the robot to be quickly configured for specific tasks by step-by-step image acquisition and evaluation in the vision sensor configuration software.

This extensive integration capability not only saves time, but also minimizes risk in the application. Thanks to matching robot apps, simple tasks can be solved quickly and effectively without the need for specific knowledge of robot programming. This means that even less experienced users can work quickly and effectively with the VISOR® Robotic.

Easy communication with robots from leading manufacturers

The VISOR®-Robotic vision camera can easily communicate with leading robot manufacturers. You can easily request the right library or app for your robot using the form below.

Picking up parts

Supply systems in a production line are becoming more and more versatile. In addition to universal trays, parts can be supplied extremely flexibly with linear vibrators. Thanks to the VISOR® Robotic, components/parts can be reliably located and gripped with both feeding options.

When loose components are delivered, the sensor not only checks their position, but also inspects the free space around the object for the gripper. The VISOR® sends this information to the robot controller.

Error-free communication between the vision camera and robot controller is fundamental, as the process is controlled with this information - grabbing the object or activating the linear vibrator. The application can also be flexibly adapted to individual transport options of goods without the need for an expensive centering device.

The VISOR® detects the position and filling level of the tray and forwards this information to the robot. If the camera is mounted stationary, it has no effect on the cycle time.

Video: Picking up parts from a conveyor belt

Placing parts

What happens after the parts are picked up by the gripper? The VISOR® Robotic also provides important information for the next process steps and demonstrates its skills in robotic applications, such as screw placement, clip mounting or adhesive application. Object position detection is effortless; even when the position of the object changes. This ensures a higher production quality.

Knowing the exact position of a windscreen in the bodywork ensures, for example, the accurate placement of a windscreen. The mechanical effort is reduced and the production line becomes even more flexible. The VISOR® Robotic concept enables direct communication between the VISOR® and the robot, an additional controller is no longer necessary for many applications.

Video: Placing and automatic insertion of parts

VISOR® calibration plate

Calibration is done using a calibration plate. By following the steps in the calibration program, the coordinates of the robot are processed in the vision camera. In addition to the possibility of using a calibration plate, it is possible to calibrate the vision camera using the 'point-to-pair'.

Automatic correction of errors caused by distortion ensures accurate results. There are four different versions for different field of views and distances.

VISOR® Robotic +Z for advanced distance measurement

With the VISOR® Robotic +Z, SensoPart has added a camera with integrated distance measurement for robotics applications to its vision camera range. This camera has an impressive range of up to 2500 mm and operates at a frequency of 100 Hz, making it suitable for various applications.

Taking distance measurement to the next level

The VISOR® Robotic +Z has been specially developed to take distance measurement in robotics to the next level. By integrating an external projection laser, this camera is ultra-compact and of very high quality, making it ideal for long-distance triangulation measurements, for example.

Perfect combination

Users can easily adjust imaging settings such as resolution, working distance and distance calibration. What makes the VISOR® Robotic +Z truly special is the perfect combination of 2D vision-guided robotics with advanced distance measurement. Integration with the new Yaskawa Robot Library V2.0 ensures an optimal user experience. Read more about the VISOR Robotic +Z camera with distance measurement.